For millennia, human civilizations have defined their ages by the dominant materials of their time: Stone, Bronze, Silicon. Now, Nobel laureate Omar Yaghi argues that a new age is dawning, driven by a revolutionary class of materials known as metal-organic frameworks (MOFs) and covalent organic frameworks (COFs). These crystalline structures, pioneered in the 1990s, possess unparalleled porosity – effectively creating materials where the internal volume vastly exceeds their external size. This discovery, recognized with the 2025 Nobel Prize in Chemistry, is poised to reshape industries from water harvesting to carbon capture.

The Breakthrough: Harnessing Molecular Construction

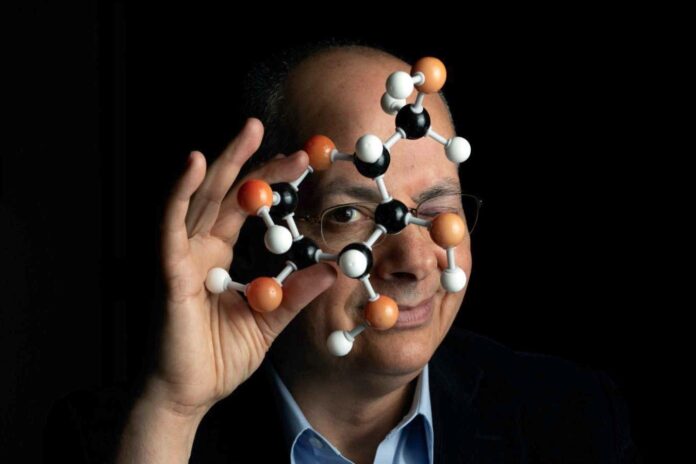

Yaghi’s work centers on “reticular chemistry,” the precise assembly of materials at the molecular level. Unlike traditional material synthesis, which often results in disordered structures, reticular chemistry aims for perfect, repeating crystalline forms. The challenge was immense; nature itself favors disorder, making the creation of stable, ordered materials at scale seem impossible.

However, in 1999, Yaghi’s team synthesized MOF-5, a zinc-based material with an unprecedented surface area – a few grams equivalent to a football field’s worth of internal space. This breakthrough revealed the potential of MOFs and COFs: materials capable of selectively trapping gases, extracting water from arid air, and revolutionizing chemical processes.

From Intellectual Curiosity to Societal Impact

Initially driven by a purely intellectual challenge – the desire to construct materials molecule by molecule – Yaghi’s research quickly evolved toward addressing real-world problems. The key to stability lies in carefully controlling the synthesis environment, allowing for the formation of ordered structures. Once mastered, the extraordinary porosity of MOFs and COFs opened doors to applications previously considered unattainable.

“When you know how much porosity these materials have, you immediately think about trapping gases,” Yaghi explains. “These materials encompass compartments of space where a molecule of water or carbon dioxide… can sit.” This fundamental property is now being leveraged in technologies designed to extract water from desert air (even in humidity below 20%) and capture carbon dioxide directly from the atmosphere.

Scaling Up: From Lab to Industry

Yaghi’s company, Atoco (founded in 2020), is driving the commercialization of these materials. Recent advancements include COF-999, a highly efficient carbon-capture material tested for over 100 cycles in Berkeley, and devices capable of harvesting thousands of liters of water per day.

The long-term vision extends beyond current applications:

- Sustainable Production: MOFs and COFs can be disassembled in water without releasing harmful residues, addressing potential waste concerns.

- Energy Efficiency: Utilizing waste heat and ambient sunlight to power capture/release cycles reduces energy consumption.

- AI-Driven Design: Artificial intelligence is accelerating the optimization of MOF and COF properties, shortening development cycles.

The Future of Materials: Heterogeneity and Catalysis

While current research focuses on optimizing existing materials, Yaghi’s lab is exploring “multivariate materials” – structures with intentionally uneven internal environments. By combining ordered skeletons with heterogeneous “guts,” these materials could achieve unprecedented selectivity and efficiency in gas absorption and chemical reactions.

Moreover, MOFs and COFs hold promise in catalysis, potentially replicating the efficiency of enzymes for industrial chemical synthesis. This could lead to faster, more sustainable production of pharmaceuticals and other vital compounds.

“We are going through a revolution,” Yaghi asserts. “We can design materials like we’ve never done before, and connect them to uses like we have never done before.”

The exponential growth in patents related to MOFs and COFs suggests that this revolution is already underway. As research converges with engineering and artificial intelligence, reticular chemistry is poised to define a new age in materials science – an age where materials are not just assembled, but precisely designed for a sustainable, efficient future.